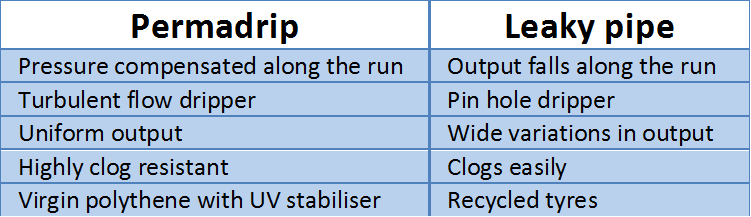

Porous hoses and ‘Leaky Pipe’ type drip systems are very popular; but are they as technically capable as commercial drip lines such as Permadrip?

One consideration when designing an irrigation system is the output. Not only do we need to know how much water is being applied, we also need to be sure that the amount of water supplied to the plants at the start of the system will be the same as the plants situated at the far end. If not, some plants will be too wet – wasting water, whilst others will be too dry. With Permadrip, each dripper is ‘pressure compensated’ so every dripper delivers the same amount of water (1.6 litres per hour) regardless of whether the dripper is at the beginning of the run or the end of the run. In contrast many porous pipe systems can only give a rough indication of output, and this output will fall along the length of the pipe.

Another vital consideration when specifying drip lines is the life expectancy. Permadrip is made of a thick walled, UV stabilised polythene with a 10 year life expectancy. Although a filter is always recommended, each dripper has a built-in self-flushing mechanism to minimise any blockage problems. Porous pipe systems, by contrast have extremely small dripper ‘pores’ that are much more prone to blocking over time.

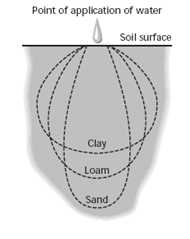

Porous pipe systems release water along their entire length to create a continuously watered band, whereas Permadrip have drippers every 300mm or 500mm – which is better? With Permadrip, as the soil surface is kept mostly dry, evaporation losses are reduced and weed growth discouraged. Beneath the soil surface, the capillary action of the soil will cause the moisture to spread outwards in an inverted cone shape, ensuring an adequate water supply to the plant roots.

Porous pipe systems release water along their entire length to create a continuously watered band, whereas Permadrip have drippers every 300mm or 500mm – which is better? With Permadrip, as the soil surface is kept mostly dry, evaporation losses are reduced and weed growth discouraged. Beneath the soil surface, the capillary action of the soil will cause the moisture to spread outwards in an inverted cone shape, ensuring an adequate water supply to the plant roots.

Permadrip is manufactured as a commercial grade product in state-of-the-art manufacturing facilities. Manufactured in Israel by some of the world’s leading irrigation manufacturers, the drip line is the product of many year’s R&D effort.