Trapped air can cause problems in any system with water pipes. Taps, washing machines, showers, toilet cisterns in fact anything that has a direct connection. This includes irrigation systems whether working directly off the mains water supply or indirectly via water storage tank and pump.

How can you tell if you have trapped air in your watering system?

Well, if you turn on a tap and it coughs and splutters and doesn’t give a full flow. Or a solenoid valve judders when it opens or closes. The reason is usually an airlock, vapour is less dense than liquid it can end up at the highest points on the system which is usually a valve or end of pipework run and if not purged it can restrict or even stop the water flowing.

This type of problem usually occurs after something has recently been installed such as new supply pipework to an outside tap, water storage tank or a new valve manifold.

If you have a pumped system, always check the suction side. If clamps are loose or pipework not fitted correctly this can introduce air into the system.

But beware many fittings have areas within them that can hide not only air but also debris such as solder, plastic swarf from drilled saddles or chamfered pipes which can cause a similar problem. Therefore, it is most important to try and avoid getting debris into the system in the first place or if this is unavoidable then to make sure the pipework is properly flushed out prior to connection.

In the case of new pipework when first installed the pipe was obviously just filled with air otherwise whoever installed it would have got rather wet. Therefore, unless this air has been fully purged out it may stay trapped and cause issues. This may be a simple job to rectify or more involved if the pipework run and fittings are complex.

How can it be fixed?

Well, if you can identify the section of pipework or fitting causing the problem, then go straight for that. In the case of new pipework isolate the water to that section and open any taps, valves or drain points fitted. Allow any water within to flow out to purge the pipework and fittings. Slowly turn on the water supply and making sure the flow is constant and uninterrupted close any opened fittings leaving the furthest away till last.

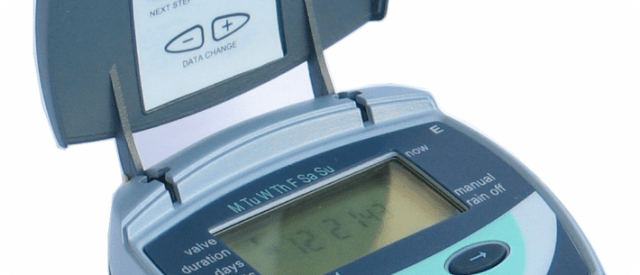

If the problem is a with a solenoid valve the Hunter PGV type has a bleed screw especially for the purging of air within it, simply loosen this to allow the air to escape then retighten. Always check valve operation both manually and automatically after any remedial work.

If your system has a pressure vessel always check that the inner membrane is sound. An indication that it isn’t is a system that judders and switches on/off rapidly rather than runs for a while before switching off. When checking the pressure, if water comes out of the valve this means the membrane has split and it will need replacing.

It is always advisable to contact a professional plumber for advice or rectification of any plumbing fault.